While we use different types of products every single day, we don’t think much about how those products were made. Injection molding services make up a huge chunk of how most products that we use are made. Let’s go over what injection molding is and how it works.

While we use different types of products every single day, we don’t think much about how those products were made. Injection molding services make up a huge chunk of how most products that we use are made. Let’s go over what injection molding is and how it works.

What Is It?

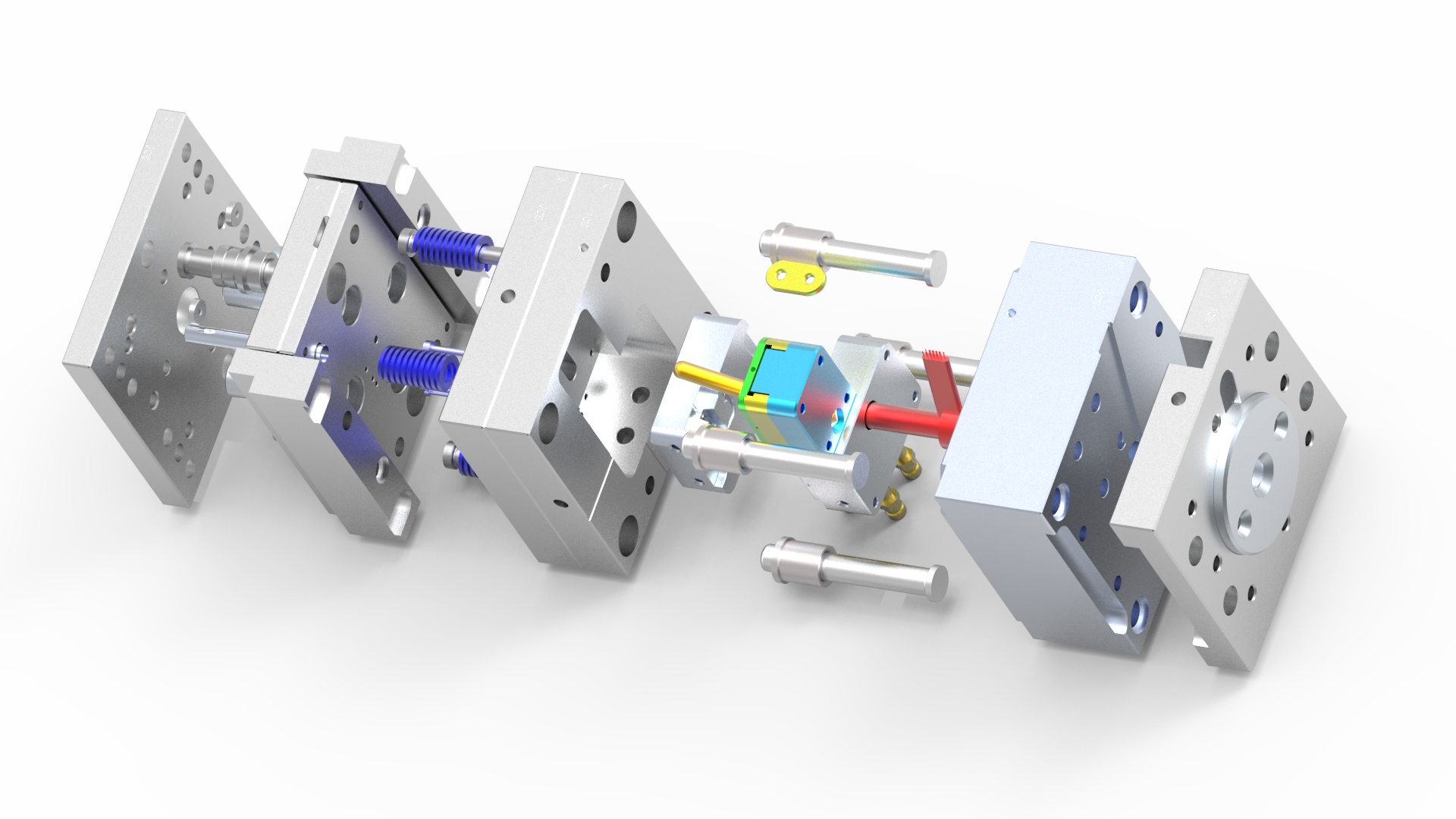

Injection molding is a manufacturing process in which one part can be made thousands or even millions of times in succession. The idea is to create a mold of the product you are making, and then using that same mold to make a lot of product quickly in bulk.

One of the largest advantages of injection molding is it’s one of the best manufacturing methods to reduce scrap. Injection molds have reduced scrap because most of the plastic sheet is being used for the mold which reduces the amount of plastic that needs to be cut away.

Because you are using one mold, it also reduces the price by quite a bit when creating a lot of products at scale. This is the main reason why injection molding is so popular as companies can save a ton of money when they need to produce large quantities of one type of product.

Things To Consider

One of the things to consider when thinking of using plastic molding is your financial cost constraints. While per piece, the cost is very low when using this method, there is however a high initial investment cost required to set up the project. Make sure you understand that this is just how injection molding works but that in the long run, you will be saving a ton of money using this process over other fabrication processes when creating products in bulk.

As you can see, injection molding is a pretty neat way to get something made at scale while not breaking the bank.